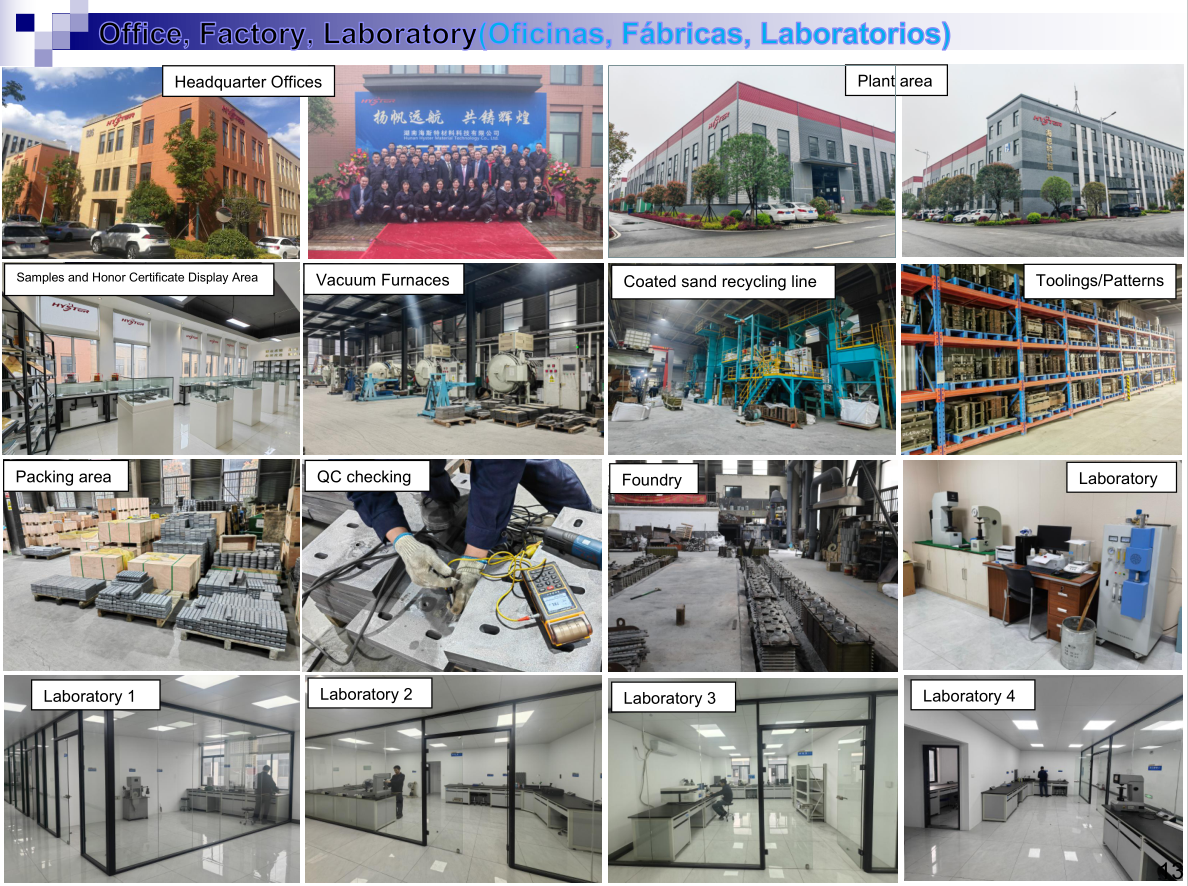

Factory Show

Home>Factory Show

Hunan Hyster Material Technology Co., LTD. owns total 4 factory buildings in Hunan province of China, with all necessary laboratory devices and various honorary certificates on Quality, Safety, Environment, High-tech, Integrity management, etc.

Hunan Hyster Material Technology Co., LTD. was founded in 1995 and located in Changsha city, Hunan province, middle of China, covers more than 8000 square meter production site area. We are a professional manufacturer & exporter of composite Bi-metallic wear blocks/wear plates(White Iron brazed with mild steel, hardness 63HRC/725 BHN), high chromium wear castings, Ni-hard wear Liners/Billets, Chromium carbide overlay wear plates, and other metallic wear castings, mainly serve for industries such as Mining, Quarrying, Material conveying systems, Sugar Cane Milling, Iron Mill/Steel Plant, Cement, Sand, Gravel, Dredging, Crushing etc.

Our annual output of bi-metallic wear blocks/bars/plates is more than 4000tons, capable to produce about 1200 different sizes and shapes; annual output of metal wear-resistant castings is more than 6000 tons.

1. Typical wear materials

--Wear castings: include HST white iron castings, Ni-hard wear castings, high chrome white iron castings, high manganese steels and other alloy cast steels. mainly application for bucket/bucket teeth, Track shoe, Blow bar, Jaw plate, Guard board, Hammers of crusher, liner plate, sieve plate etc.

--Bi-metallic wear castings: main material is white iron compound with mild steel backing, can make to different shapes, include straight pipe, elbow pipe, and sweep tee, main application for bucket wear protection, dredger attachments, plates of crusher, chute/hopper wear protection, and other liner plate of conveying equipment.

--Overlay wear plates: mainly application for liner protection of conveying equipment, Chute/ Hopper wear protection.

--Surfacing welding/Hardfacing/Cladding: mainly plasma surfacing, with low rate of dilution, high hardness, can also surface non metallic resistant materials (such as ceramic).

2. Manufacturing facilities

--Foundry equipment: precision castings, shell casting, (sodium) silicate bonded sand casting, lost foam casting, steel mould castings.

--Welding: vacuum brazing furnace, plasma spray welding machine, CO2 gas shield welding machine, high frequency welding, hand arc welding machine.

--Machining: saw machine (vertical saw, horizontal saw), grinding machine, milling machine (vertical milling, horizontal milling),lathe, drilling machine, wire cutting machine.

--Heat treatment facility: heat treatment furnace.

--Surface treatment: chain shot blasting machine; Wheel type shot blasting machine.

--Shaping equipment: trimming machine, oil press machine

--Various fixture tools, and transport equipment.