Wear buttons

Brand : HYSTER

Product origin : China

Delivery time : within 7-20days

Supply capacity : 100 tons per month

Hyster Laminated Chrome White Iron Wear Blocks and Wear Plates are unique wear resistant materials in that they combine very high wear resistant qualities of a white iron(ASTM A532 15/3CrMo, 700BHN–63HRc) with a weldable & high impact toughness mild steel through a metallurgical bond to create a product that is exceptionally resistant to impact and abrasion while retaining.

--Material: ASTM A532 CLASS II TYPE B Chrome white iron vacuum brazed onto mild steel base plate.

Advantage:

1. Hardness: 63HRC/700BHN. According to the feedback from our end users, the usage life is at least 2 times higher compared with overlay/hardfacing wear plates, at least 7 times longer than A.R type steels 360/400BHN. The thicker ones such as 20mm or above wear plates, usage life is much more longer. The wear resistant performance is the same from plate surface to the brazing joint.

2. Wear plate surface is smooth and flat, media is not easy to stick on.

3. Shapes and sizes can be made on request; Bolts, Nuts, Washers, Holes, Threads are available on request.

4. Better cost-efficient.

5. Operating temperature: 550℃

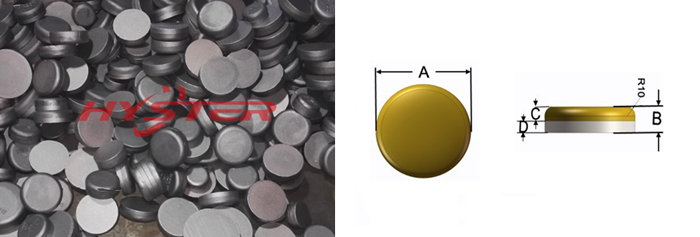

Wear Buttons

Some other brand name: Duabutton, Vidabutton etc.

Very easy to use, no pre or post heating when welding. Available in diameters from 60mm up to 150mm. Develop your own layout and pattern to suit your particular wear protection solution.

Wear button blocks are extensively used on heavy earth moving equipment, particular on mining and construction buckets and shovels, heavy earth moving equipment etc. Ideal for smaller areas that require materials resistant to abrasion and impact.

Our wear buttons can also be used together with chocky blocks for better wearing protection

Standard Dimensions and Weight:

Other sizes can be made on request

Item No. | Size (mm) | Dimension(mm) | N.W. (kg) | |||

A | B | C | D | |||

WB 60 | ∅60x27 | 60 | 27 | 17 | 10 | 0.7 |

WB 75 | ∅75x27 | 75 | 27 | 17 | 10 | 0.8 |

WB 90 | ∅90x27 | 90 | 27 | 17 | 10 | 1.4 |

WB 110 | ∅110x32 | 110 | 32 | 20 | 12 | 2.1 |

WB 115 | ∅115x32 | 115 | 32 | 20 | 12 | 2.5 |

WB 150 | ∅150x41 | 150 | 41 | 25 | 16 | 5.7 |

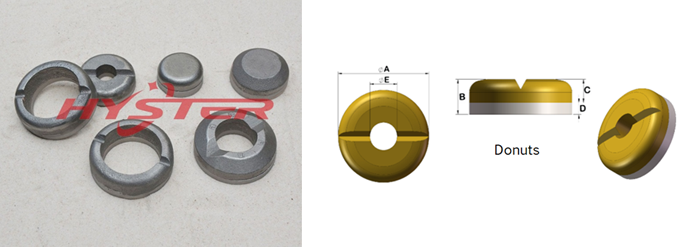

Wear Donuts

They are often effectively used on a variety of buckets, loaders, excavators, earth moving equipment, draglines and bolt protection etc. with any layout of pattern designed to suit your particular wear area, providing maximum protection and security while minimizing the effects of heavy impact.

Wear Donuts can be made to different sizes as required

Standard Dimensions and Weight:

Other sizes can be made on request

Item No. | Alternative Item No. | Size (mm) | Dimension(mm) | N.W. (kg) | ||||

A | B | C | D | E | ||||

WD 75 | DLP 1920 | ∅75x25 | 75 | 25 | 17 | 8 | 25 | 0.7 |

WD 100A | DLP 1921 | ∅100x25 | 100 | 25 | 17 | 8 | 50 | 1.0 |

WD 100B | DLP 1994 | ∅100x32 | 100 | 32 | 24 | 8 | 70 | 1.0 |

WD 130 | DLP 2196 | ∅130x23 | 130 | 23 | 15 | 8 | 80 | 1.3 |

WD 148 | DLP 4471 | ∅148x35 | 148 | 35 | 25 | 10 | 108 | 2.2 |