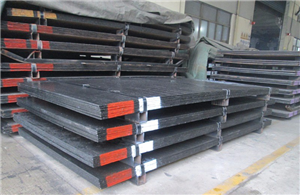

Hardfacing wear plates

Brand : Hyster

Product origin : China

Delivery time : 5 days

Supply capacity : 160 tons per month

China Professional supplier for Chromium carbide hardfacing wear plates

| Product Name | Hardfacing wear plate, overlay wear resistance steel plate, Cladded wear plates, High chromium carbide overlay plates, overlay wear plates |

| Technique | Hardfacing, open arc welding, submerged arc welding |

| Special Use | Chute wear liner, hopper wear liner, bucket wear protection etc. |

| Material | Q235/Q345G with high chromium carbide overlay/hardfacing |

| Width | 50-1500mm |

| Overlay Thickness | 4mm-30mm |

| Customized | Yes |

| Standard | AISI, ASTM |

| Chemical composition | C: 4.0-5.0% Cr:25-40% |

| Hard-facing layer hardness | 58-65HRC |

| Wear resistant temperature | <500℃ |

| Microstructure | Carbide (Cr7C3)volume fraction above 50% |

Features & Benefits

● Cost effective solution when compared to traditional abrasion-resistant steels

● Recommended for resistance to wear by abrasion, fretting, cavitation, and particle erosion in high temperature applications (up to 1100°F).

● Ideal for mild to moderate impact abrasion resistance.

● Low maintenance cost and easy installation.

● The overlay surface of CCO plate will consist of a series of beads with numerous hairline cracks in them. These properly spaced crosscheck cracks are a natural phenomenon and are beneficial to the material. The cracks propagate through the overlay and end at the fusion line.

| Standard Overlays | Weight | Standard Sheet Size(mm) | Overall Thickness |

| sq/m(kg) | |||

| 4 ON 4 | 62 | 1500x3000 / 1200x2400 | 8 |

| 4 ON 6 | 78 | 1500x3000 / 1200x2400 | 10 |

| 6 ON 6 | 94 | 1500x3000 / 1200x2400 | 12 |

| 5 ON 8 | 102 | 1500x3000 / 1200x2400 | 13 |

| 6 ON 8 | 109 | 1500x3000 / 1200x2400 | 14 |

| 8 ON 8 | 126 | 1500x3000 / 1200x2400 | 16 |

| 5 ON 10 | 118 | 1500x3000 / 1200x2400 | 15 |

| 6 ON 10 | 126 | 1500x3000 / 1200x2400 | 16 |

| 8 ON 10 | 141 | 1500x3000 / 1200x2400 | 18 |

| 9 ON 10 | 149 | 1500x3000 / 1200x2400 | 19 |

| 10 ON 10 | 157 | 1500x3000 / 1200x2400 | 20 |

| 12 ON 12 | 188 | 1500x3000 / 1200x2400 | 24 |

| 17 ON 12 | 222 | 1500x3000 / 1200x2400 | 29 |

Application Specifications

● Cutting – Plasma burning, air arc, abrasive saw or water jet.

● Welding – Our CCO overlay plate can be joined by welding the substrate to substrate using 309 weld wire/rod.

● Bending – Using a press brake, forming should be perpendicular to the weld pass direction.

● Plate rolling should be performed in the directions of the overlay beads.

Overlay weld bead can be in direction of length!