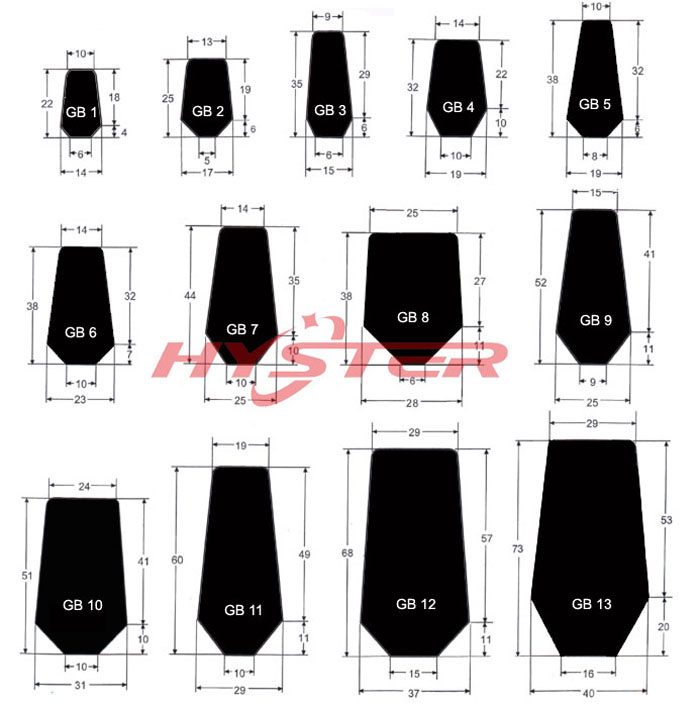

Grouser bar hard surfacing

Brand : Hyster

Product origin : China

Delivery time : 5 days

Supply capacity : 200 tons per month

High strength Low alloy Grouser bar hard surfacing

Hyster can make grouser bars in length of 200-700mm.

Material: low alloy cast steel.

Hardness: 400-450HB

Hyster developed HS 63HRC is mixed withalloy powder with a high density of primary chromium carbides in an iron matrixand non-metallic powders. It is the best cost-effective choice for high wearapplication compared to Tungsten carbide. Abrasion resistance is very high,with moderate impact resistance, hardness could achieve to 63-65HRC.

| Hardness HRC | 1 | 2 | 3 | 4 | 5 | 6 | Average |

| Position 1 | 60.5 | 61 | 61.5 | 62.5 | 62 | 60 | 61.25 |

| Position 2 | 64 | 62 | 63.5 | 64 | 63 | 63.5 | 63.33 |

| Position 3 | 65 | 64 | 64.5 | 63.5 | 65 | 64 | 64.17 |

Typical Applications

● Grouser bar hard surfacing

● Bucket teeth hard surfacing

● Heel shroud hard surfacing

● Shredder hammer hard surfacing

● Wear plate hard surfacing

● Crusher blade hard surfacing

● Dredger hard surfacing

● Break shovel hard surfacing

● Cutter tip hard surfacing

FAQ. What is the longest service life that products with HS 63hard surfacing?

A. This is a hard question to answerbecause there are so many variables, especially in hardfacing cutting edges, blades and partsexposed to wear from abrasion, impact, erosion, etc. Generally, anincrease in wear life of 4 to 5 times can be expected for parts that arenot hardfaced. Wear parts that are currently beinghardfaced can expect a 2 to 4times improvement in wear life.