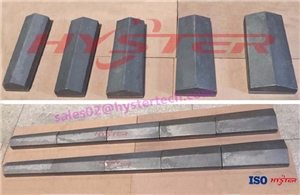

Grizzly bars

Brand : HYSTER / OEM

Product origin : China

Delivery time : Within 7-20days

Supply capacity : 100 tons per month

Grizzly bars

Other brand name: Domite Grizzly Bars, Grizzlybars

High Chrome White Iron ASTM A532 Grizzly Bars 700BHN

Material: ASTM A532 15/3CrMo Class II Type B High Chrome White iron, with weldable mild steel.

Hardness: 63HRC/ 700BHN

Very excellent abrasion resistance and impact tougness.

Superior wear resistance For Crushing and Screening industries.

Long Life -- Proprietary High Carbon ASTM A532 White Iron with 700 BHN hardness to provide extremely good resistance to severe most of the wear applications. Metallurgically bonded to a weldable steel plate. Impact will not destroy the integrity of the wear resistant face.

Adaptability --Standard carbon steel weld processes are suitable, with no special procedure or preheat requirements. As an alternative to welding, studs can be easily attached or any shape of bolt or screw hole can be incorporated.

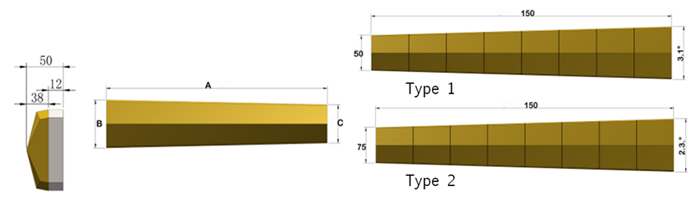

Standard Dimensions and Weight:

TYPE | HYSTER ITEM NO. | Alternative Item No. | SIZE(MM) | Dimension | N.W(kg) | ||

A | B | C | |||||

1 | GB1-105 | DLP 2067 | 150x137.5 | 305 | 150 | 137.5 | 13.6 |

GB1-137.5 | DLP 2068 | 137.5x125 | 305 | 137.5 | 125 | 12.5 | |

GB1-125 | DLP 2069 | 125x112.5 | 305 | 125 | 112.5 | 11.2 | |

GB1-112.5 | DLP 2070 | 112.5x100 | 305 | 112.5 | 100 | 10 | |

GB100 | DLP 2071 | 100x87.5 | 305 | 100 | 87.5 | 8.8 | |

GB1-87.5 | DLP 2072 | 87.5x75 | 305 | 87.5 | 75 | 7.5 | |

GB1-75 | DLP 2073 | 75x62.5 | 305 | 75 | 62.5 | 6.3 | |

GB1-62.5 | DLP 2074 | 62.5x50 | 305 | 62.5 | 50 | 5.1 | |

2 | GB2-150 | DLP 2075 | 150x141 | 305 | 150 | 141 | 13.8 |

GB2-141 | DLP 2076 | 141x131 | 305 | 141 | 131 | 12.9 | |

GB2-131 | DLP 2077 | 131x122 | 305 | 131 | 122 | 11.9 | |

GB2-122 | DLP 2078 | 122x113 | 305 | 122 | 113 | 11.1 | |

GB2-113 | DLP 2079 | 113x103 | 305 | 113 | 103 | 10.1 | |

GB2-103 | DLP 2080 | 103x94 | 305 | 103 | 94 | 9.2 | |

GB2-94 | DLP 2081 | 94x84 | 305 | 94 | 84 | 8.3 | |

GB2-84 | DLP 2082 | 84x75 | 305 | 84 | 75 | 7.4 | |

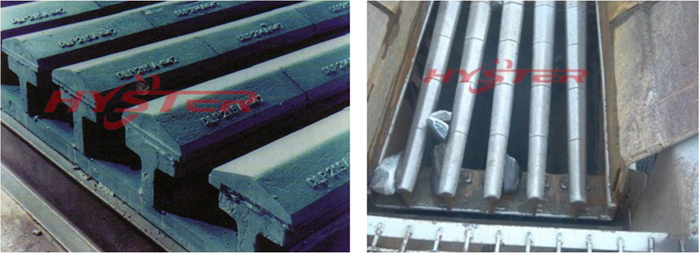

Application Photos:

Other wear items that Hyster supply:

----Hyster White Iron Wear Block(700BHN-63HRC) Range of products based on a composite white iron wear surface metallurgically bonded to a weldable mild steel backing plate. Wear block is fixed to the surface of fixed and mobile plant equipment, such as mining buckets and chutes, where protection from severe abrasion is required.

----Hyster Overlay Wear Plates--Chromium carbide clad wear plate manufactured in HYSTER and marketed worldwide. Overlay plate is well suited to fixed and mobile plant equipment associated with the construction, mining and resource industries; particularly iron ore, coal, cement and steel applications.

----Hyster NiHard--Abrasion and high impact resistant product. It is often cast into billets and liners and used extensively in the mining, construction and mineral processes industries, particularly in bulk handling situations.

----Hyster Tungsten Carbide—High standard abrasion resistant product. It is often used where the application has no impact force or very slightly impact.

Features and Benefits

Reduced Maintenance

• Protects any high wear area, eliminating the need for frequent rebuild or replacing wear plate

• Lasts longer than other wear protection

• Excellent alternative to hard facing which can lead to cracking of major structural components Increased Productivity

• Reduced maintenance ensures maximum machine availability

• Wide variety of shapes and sizes allows small areas to be protected, minimizing the affect on penetration and material flow

Lower Operating Cost

• Can be fit to flat or curved surfaces, eliminating the need to have wear plate formed to fit

• Bucket life is significantly increased, minimizing repair and new bucket orders

Typical Data Numbers:

>white iron wear blocks life is 50% greater than that of Ni Hard Irons.

>At least 7 times longer than A.R. type steels 360/400 BHN

>5 times the wear rate of Manganese Steel

>3 times the wear rate of Tapco Weld Hardfacing

>4 times the wear rate of Astralloy-Vulcan

>16 times the wear rate of Carbon Steel

>3 times the wear rate of 500 BHN A.R. Plate

Please contact us if you have any inquiry. thank you!