CrC Overlay wear plates

Brand : HYSTER, OEM

Product origin : China

Delivery time : 5 days

Supply capacity : 200tons per month

HYSTER OVERLAY-W Series Chromium Carbide Compound Plate / EQUAL TO BRADKEN D60

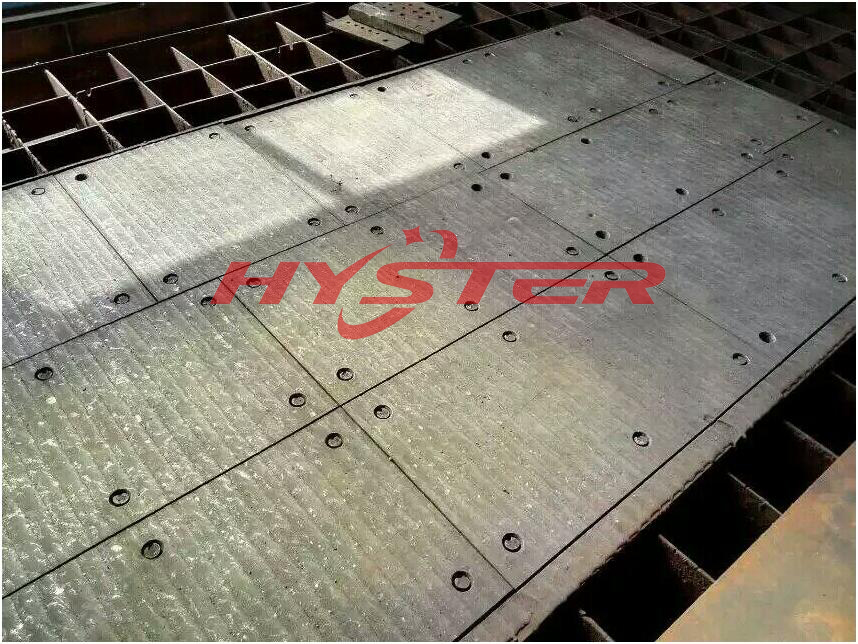

HYSTER OVERLAY-W Series Chromium Carbide Compound Plate is welded by chromium carbide overlay on a mild steel backing plate. Manufactured by our own design's welding machine with exclusive technique. It has excellent performance in wear resistant.

HYSTER OVERLAY-W Series Chromium Carbide Compound Plate is good for general application with high abrasion and moderate impact.

1) Chemical Composition C 3.5% ↑, Cr 20% ↑, Mn ※, Si ※, Fe ※;

2) Base Material Standard: SS400 MILD STEEL Stainless or others could be requested.

3) Hardness: HRC 58-62

4) Dimension Standard Thickness: 8(4+4); 10(6+4)mm; 12(6+6)mm; 13(8+5)mm; 14(8+6)mm; 20(10+10)mm

Standard Size: 1,200×2,400mm; 1,500×3,000mm

Customized Thickness & Size Available

5) Tolerance ± 1mm; 6) Heat Resistance: Maximum: 350˚C

7) Microstructure Mixture of high volume hexagonal shaped chromium carbide in tough austenitic and martensitic matrix.

Volume Fraction Primary Carbides: 30%

8) Cold Forming Minimum Radius: 200mm( for 6+4 ). Suggested: using hydrolic press to bend HYSTER-PLATE

9) Cutting Plasma( from backing plate side ) / Laser Cutting / Water Jet Knife;

-----Applications ----

-ASH LINES -BLAST FURNACE BELL & BURDEN

-ELBOW -SINTER PLANT

-BUCKET & LIPS -DRAG LINES

-CHUTE & HOPPER LINERS -DUCT

-CLASSIFIER -FAN BLADES & HOUSINGS

-MINE CAR LINERS -CYCLONES

-ORE CHUTES -DISCHARGE FUNNELS

-SLAG CHUTES -DREDGE PUMP SIDE PLATES

-EXTENSION RING -GRIZZLY BARS

-CEMENT KILNS -VIBRATOR PAN FEEDEER LINER

-SINTER BREAKER BAR -CONVEYOR CASINGS

-GREEN WALT CRUSHERS

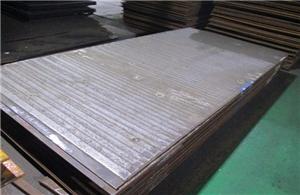

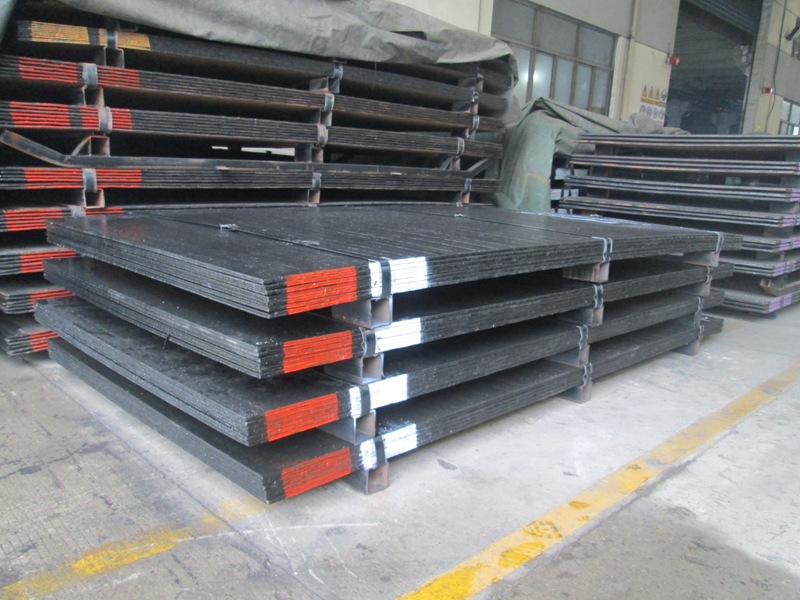

Product Photos

HYSTER OVERLAY-WI Series Complex Carbide Compound Plate / EQUAL TO BRADKEN D80

HYSTER OVERLAY-WI Series Complex Carbide Compound Plate is welded by chromium carbide overlay on a mild steel backing plate. Manufactured by our own design's welding machine with exclusive technique. It has excellent performance in wear resistant.

HYSTER OVERLAY-WI Series Complex Carbide Compound Plate is good for high abrasion and high impact wear resistant!

HYSTER OVERLAY-WN Series Chromium Carbide Compound Plate / EQUAL TO BRADKEN D90

HYSTER OVERLAY-WN Series Chromium Carbide Compound Plate is welded by chromium carbide overlay on a mild steel backing plate. Manufactured by our own design's welding machine with exclusive technique. It has excellent performance in wear resistant.

HYSTER OVERLAY-WN Series Chromium Carbide Compound Plate is good for severe sliding abrasion and fine particle abrasion, but low impact resistant.

If you have any questions or interests, please just contact us and shot an email, thank you!

- Download

- HYSTER OVERLAY WEAR PLATES 2018.pdf