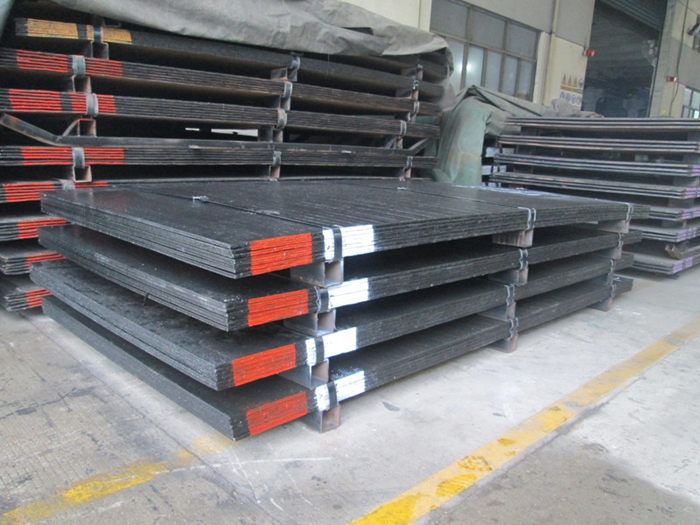

Chromium carbide compound wear plates

Brand : HYSTER

Product origin : China

Delivery time : 5 days

Supply capacity : 160 tons per month

Chromium carbide compound wear plates

Chromium carbide compound wear OVERLAY-PLATEis welded by chromium carbide overlay on a mild steel backing plate.Manufactured by our own design's welding machine with exclusive technique.

Chromium carbide compound wear OVERLAY-PLATEhas excellent performance in abrasion resistant.

Thickness Range : 3-20 mm

Thickness error is ±0.3mm

Full Sheet Size : 1500 x 3000 mm(1480 x 3041)

1500 x 2000 mm(1480 x 2031)

Special sizes can be customized.

CHEMICAL COMPOSITION: C 4.0%~5.5% Cr 23%~35%

BACKING PLATE: Standard: SS400 mild steel or equivalent Stainless or others upon request

HARDNESS AVAILABLE: 58-62HRC AND 62-65HRC

TOLERANCES: ± 1mm

HEAT RESISTANCE: Maximum: 400˚C

MICROSTRUCTURE: Mixture of high volume hexgonal shaped chromium carbide in tough austenitic and martensitic. Average VFC above 35%.

PENETRATION TO THE BASE METAL: 1.5mm

COLD FORMING: Minimum Radius: 150mm( for 6+4 )

Suggested: using hydrolic press to bend plate

CUTTING: Plasma( from backing plate side ) / Laser Cutting / Water Jet Knife

Features & Benefits

● Cost effective solution when compared to traditional abrasion-resistant steels

● Recommended for resistance to wear by abrasion, fretting, cavitation, and particle erosion in high temperature applications (up to 1100°F).

● Ideal for mild to moderate impact abrasion resistance.

● Low maintenance cost and easy installation.

● The overlay surface of CCO plate will consist of a series of beads with numerous hairline cracks in them. These properly spaced crosscheck cracks are a natural phenomenon and are beneficial to the material. The cracks propagate through the overlay and end at the fusion line.